Add to Cart

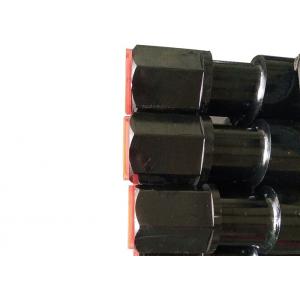

API Standard 4 1/2'' 8.56mm Drill Pipe R1 R2 For Water Well Drilling Manufacturers

Introduction

Long service life All threads and sealing surfaces should be phosphated to prevent sticking and corrosion. Wear straps and wear pads at the joints extend service life.

| Processing type | Forging |

| Machine type | Drilling Equipment |

| Type | Drill Pipe |

| Advantage | Reliable Material And Long Service Life |

| OD A | 4 1/2" |

| Wall B | 0.337" |

| Length L | 25' |

| Weight 1bs | 415 |

| Dist From ShoulderC | 3" |

| Across Flat E | 3 1/2" |

| Recess DIA F | 3 1/2" |

| Recess Location H | 3 1/2" |

| Recess Length K | 5" |

| Across Hex M | 3 3/8" |

| Connection | 4" |

| P/M | 3 1/2 Reg |

advantage

1. Alloy steel with a combination of hardness and wear resistance, provided by the country's top special steel manufacturers. (Tube thickness and material can be selected by the user).

2. Traditionally, the threads and joints between the pipe and the end piece are fragile. To address this, we friction welded the joints for maximum strength and heat treated the end pieces for optimum durability.

Drill pipe usage notes

1. New drill pipe should be pasted thread oil before connection

2. Make up and break at least 3 times before drilling

3. Hard bending and plastic coating can be processed according to costumer special requirement.

Our Services

1. Drill pipe strictly in accordance with ISO9001 standard

2. If you find a quality problem within one month of the package being returned.

3. All obligations and responsibilities are strictly performed in accordance with the contract

4. 24-hour online customer service, feel free to contact us.